Grand Forks Woolen Mill. Special to the Globe. Grand Forks, N. D., Sept. 21. – A deal has been closed which secures the location of a woolen mill here this fall. Machinery will be brought here immediately. Next year a large plant will be erected. (The Saint Paul Daily Globe, Thursday Morning, September 22, 1892, Page 1)

New Factories for Grand Forks. Grand Forks, N. D., Nov. 29. – The Grand Forks Woolen Mill company has completed its large four-story and basement brick building, and will commence to set the boilers and engines and put in the heavy machinery as fast as it arrives. (The Saint Paul Daily Globe, Saturday Morning, November 30, 1895, Page 3)

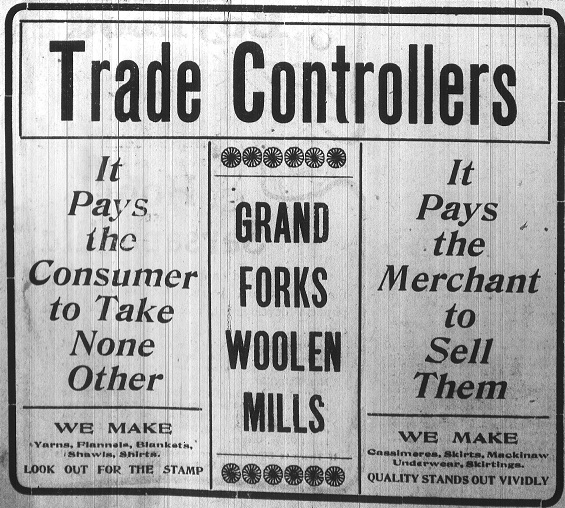

The Undersigned has just received from Grand Forks Woolen Mills his last Year’s Clip of Wool manufactured into Blankets, Flannels, Yarns, Men’s Underwear, Overshirts, and Heavy Work Jackets, &c., all of Superior Quality and Make, which must be sold within a few days. Will sell in lots or parcels to suit, at Cost. Everybody respectfully invited to inspect the goods, which are at my office, 1st door west of Court House, Warren, Minn. L. R. Lakin. (Warren Sheaf, Thursday, December 5, 1895, Page 1)

The large woolen mills at Grand Forks are doing an immense business, although they have been in operation but a short time. They are far behind now with orders, and the other factories of the state are enjoying an equally prosperous business. (The Saint Paul Daily Globe, Saturday Morning, December 14, 1895, Page 2)

Arthur Brockwell, agent for Grand Forks Woolen Mills, will be here on Saturday to buy wool for cash at highest market prices. (Warren Sheaf, Thursday, November 25, 1897, Page 5)

The Woolen Mill. One of the most important of these is the Grand Forks Woolen Mill, which, from a very small beginning, has grown to be one of the most valued institutions of the city. The manufacture of woolen goods was begun by the present proprietors of the mill in 1892, in a cheap frame building on North Third street, and the experiment, for such it was, was watched with intense interest by those who realized something of what its success would mean to the country. The need of woolen clothing in this climate was evident, and on the vast stretches of prairie land tributary to the city unlimited quantities of coarse feed suitable for sheep were annually allowed to go to waste, while out of the wheat crop was taken the cost of family clothing in addition to the other expenses to be provided for. If the wool could be successfully manufactured at home the raising of sheep could be made profitable, the cost of clothing would be decreased, and the manufacture, being carried on in the center of the grain growing district, a market right at hand would be created for a large amount of farm and garden products.

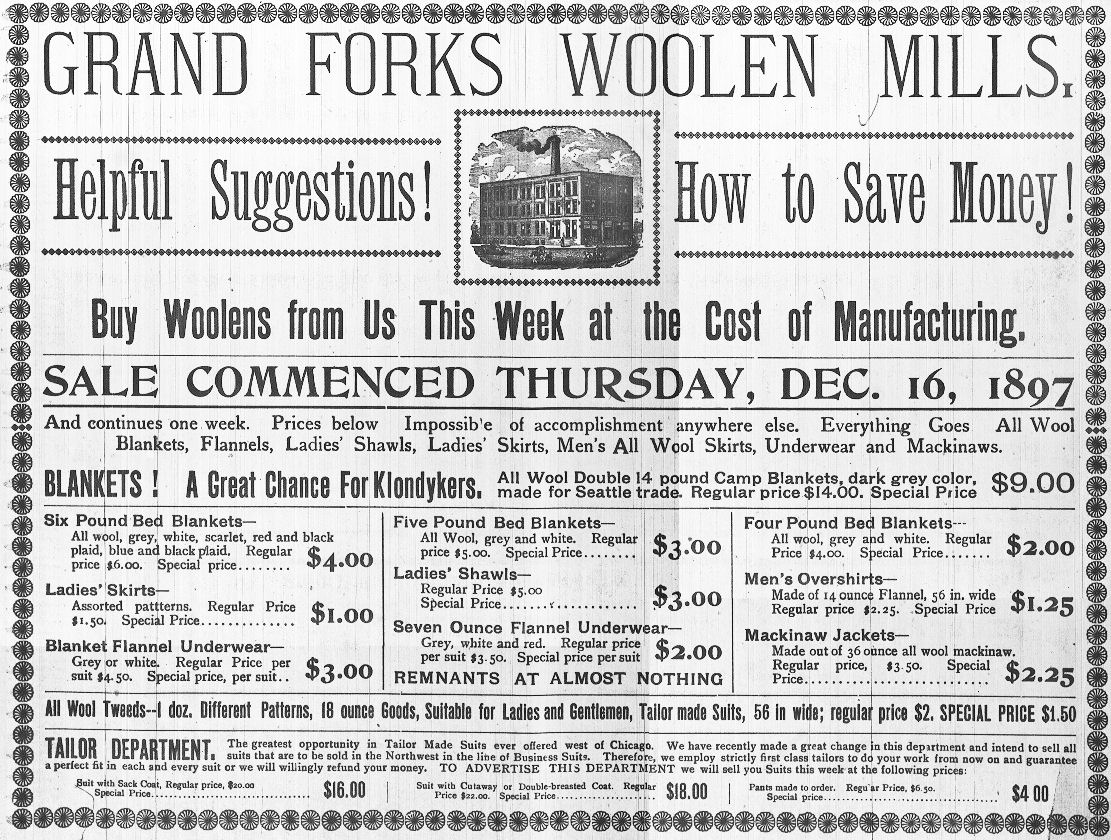

Every one at all familiar with the history of the city during the last few years knows how these hopes have been realized. The modest mill of five years ago was outgrown within two years, and, in 1895, the present handsome three-story building at the corner of Third street and Selkirk avenue was built and equipped with a full outfit of modern machinery. The trade which at first reached into two or three counties, has spread over a dozen states; carload after carload of wool has come into the city from the prairie farms, to be sent on its journey eastward, cleansed and purified, and manufactured into the various kinds of goods for which wool is suitable. The mill gives employment to from 75 to 100 persons, and has, for some time, been running night and day in all departments. Not only is the wool made up into cloth, but, under the same roof, the cloth is manufactured into clothing of all kinds, suits, pants, shirts, and underwear being made to supply merchants and individual customers. Fifteen sewing machines are kept busy on this class of work alone. Among the special lines recently manufactured is a quantity of mackinaw for the Klondike. This material is some of the heaviest ever made, weighing 48 ounces to the yard, and is of excellent quality. The mill is the largest north of St. Paul, and is the only one between the Red River and the Rocky mountains. A. P. Clifford has been manager and Claude Neilson superintendent of the mill since it was first started, and, to their energetic and careful management, the success of the enterprise is to be attributed. (Grand Forks Daily Herald, Sunday Morning, December 19, 1897, Volume 17, Number 42, Page 10)

Manager Clifford of the Grand Forks Woolen mills is in the city on his way east. The Grand Forks mills are the only institution of that kind in the state, and have grown to such a size that all flickertaildom regards them as the leading manufacturing concern of the north state. Mr. Clifford said that he was confident that the mills under his control would see a big increase in business this year and he is preparing to increase the output. The Grand Forks mills obtain their raw material from North and South Dakota and some from Montana. (The Minneapolis Journal, Thursday Evening, January 3, 1901, Page 6)

Weavers Walk Out. Ten Looms in the Mills at Grand Forks Are Idle. Special to The Journal. Grand Forks, N. D., Feb. 5. – Excitement was caused at the Grand Forks woolen mills over the action of ten of the weavers who left their looms and walked out on a strike when given notice that the old schedule of wages would again be put into effect. About two months ago, owing to the fact that there was some very slow work to be done, the management advanced the scale three-quarters of a cent per yard, but it was the intention to resume the old scale as soon as this particular piece of work was done. Yesterday morning, therefore, it was announced that the old scale would be resumed and ten of the weavers took off their aprons and filed out. It is understood they will not be taken back even if they tender their services at the old scale. The looms which they operated were idle yesterday and may be for some time. (The Minneapolis Journal, Tuesday Evening, February 5, 1901, Page 6)

L. H. Schnabel, representing the Grand Forks Woolen Mills, was in the village last Saturday. (The Princeton Union, Thursday, July 25, 1901, Page 5)

Woolens! Woolens! Just received an immense lot of Flannels from Grand Forks Woolen mills, Suitings, Worsteds, Yarns, Mackinaws, etc., to sell at 25 per cent less than manufacturer’s prices. Buy them while we’ve got them at the BIG BANKRUPT STORE, east side, opposite Winchester’s. (Warren Sheaf, Thursday, November 14, 1901, Page 5)

Wanted – 10 Operators on Pants, shirts, underwear and mackinaw clothing; good prices; will pay car fare if applicants stay six months. Address Grand Forks Woolen Mills, Grand Forks, N. D. (The Minneapolis Journal, Tuesday Evening, July 29, 1902, Page 11)

Wanted – Ten Operators on Steam power machines to make pants, shirts and Mackinaw clothing. Good wages. Fare paid. Address E. M. Rosenquist, care Grand Forks Woolen Mills, Grand Forks, N. D. (The Minneapolis Journal, Thursday Evening, August 6, 1903, Page 13)

Wanted – Weavers; Good Wages, steady work; car fare advanced. Grand Forks Woolen Mills, Grand Forks, N. D. (The Minneapolis Journal, Saturday Evening, September 12, 1903, Page 15)

Wanted – 12 Operators to Make Shirts, pants and mackinaws; guarantee $9 per week; can make $12; good prices, steady work; car fare advanced. Address Grand Forks Woolen Mills, Grand Forks, N. D. (The Minneapolis Journal, Friday Evening, August 12, 1904, Page 16)

The Grand Forks (N. D.) Woolen Mills Company has decided to quit the manufacturing of articles from the products of its mill, and has become financially interested in the Dacotah Manufacturing Company, located at St. Paul, Minn. The new company was organized some time ago by E. M. Rosenquist, superintendent of the mill company’s manufacturing department in Grand Forks, and L. H. Schnable, who traveled for the company, who interested St. Paul capital in the venture. The new company will manufacture the same lines as manufactured here and will use the products of the Grand Forks woolen mills. The new plan is much more satisfactory than the old, and the woolen mills will be devoted entirely now to the manufacturing of woolen fabrics. (American Wool and Cotton Reporter, Boston, New York and Philadelphia, Volume XIX, Number 15, April 13, 1905, Page 380)

Other attempts at factory systems have been started in the valley. For a few years woolen mills developed and the sheep industry was encouraged, but the large factory at Grand Forks soon closed its doors. One writer noted that “Sheep husbandry has never appealed very strong to our people. A few have experimented, but the level prairies, the dampness in wet weather, the lack of fences, the wolves and the dogs combined to make the life of the shepherd a strenuous one, and no man has yet followed the vocation very long.” In 1904 the six counties west of the river where the industry was most developed, had only 17,729 sheep, while they reported 99,487 head of cattle. (Collections of the State Historical Society of North Dakota, Volume III, Tribune, State Printers and Binders, Bismarck, 1910, Page 655)